THE WORLD'S LEADING SOLUTION

Eurohoist Crane Equipment ranges from 60 kg to 600 tons or more, which is capable of meeting customers’ needs in different working conditions. Besides, Eurohoist service model brings one-stop solutions to our clients. Especially in the aspect of our technology, we are continuously making new ideas, improving product quality and perfect service system because cost saving, efficiency improvement and value creation for our customers is our long-standing target. Our lifting equipment includes Electric Chain Hoist, Steel-wire Rope Type Electric Hoist, Electrical Open Winch, Single and Double Girder Bridge Crane, Portal Crane, General-purpose Overhead Crane, Light Crane systems, Slewig Jib Crane, Explosion-proof Hoist, Explosion-proof Crane, Manual Products, etc. Otherwise, in the aspect of cargo transportation, we can also provide customers with a complete set of competitive material handling solutions

PRODUCT CENTER

Automated cranes

EUROHOIST fully automatic crane is a lifting equipment that integrates automatic detection, identification, handling, path planning, remote control, automatic avoidance, fault detection, voice control and other functions.

It provides users with multi-working condition and multi-application solutions.

Main performance characteristics

①Anti-sway, precise positioning, automatic avoidance and other functions.

②Through scanning can identify the shape, position, centre of gravity and other data of the measured object.

③Industrial management system DFMES with intellectual property rights, which is an enterprise intelligent management software integrating order processing, automatic production scheduling, quality control, automatic storage and retrieval.

④With visual recognition and voice control function to realise human-machine interaction.

EUROHOIST's diverse range of fully-automatic lifting solutions can significantly reduce the cost of plant construction, compact design, compact headroom and side limit dimensions, and short cycle time (PLC-driven fully-automatic and semi-automatic cranes), which can effectively help customers to reduce capital expenditure and increase productivity. Whatever the application, we can help our customers improve efficiency.

● Safety and reliability, eliminating personal injuries and fatalities

● Improvement in operational efficiency and equipment availability Increase in total number of jobs and reduction in maintenance workloads

● Integration of lifting systems and production processes

● Increased flexibility and responsiveness of production to support real-time strategic decision-making.

Areas of application

Continuous stacking and storage processes can be mechanically managed through automated, duty-cycled, monotonous repetitive lifting and positioning, significantly reducing the risk of accidents while increasing precision and efficiency.

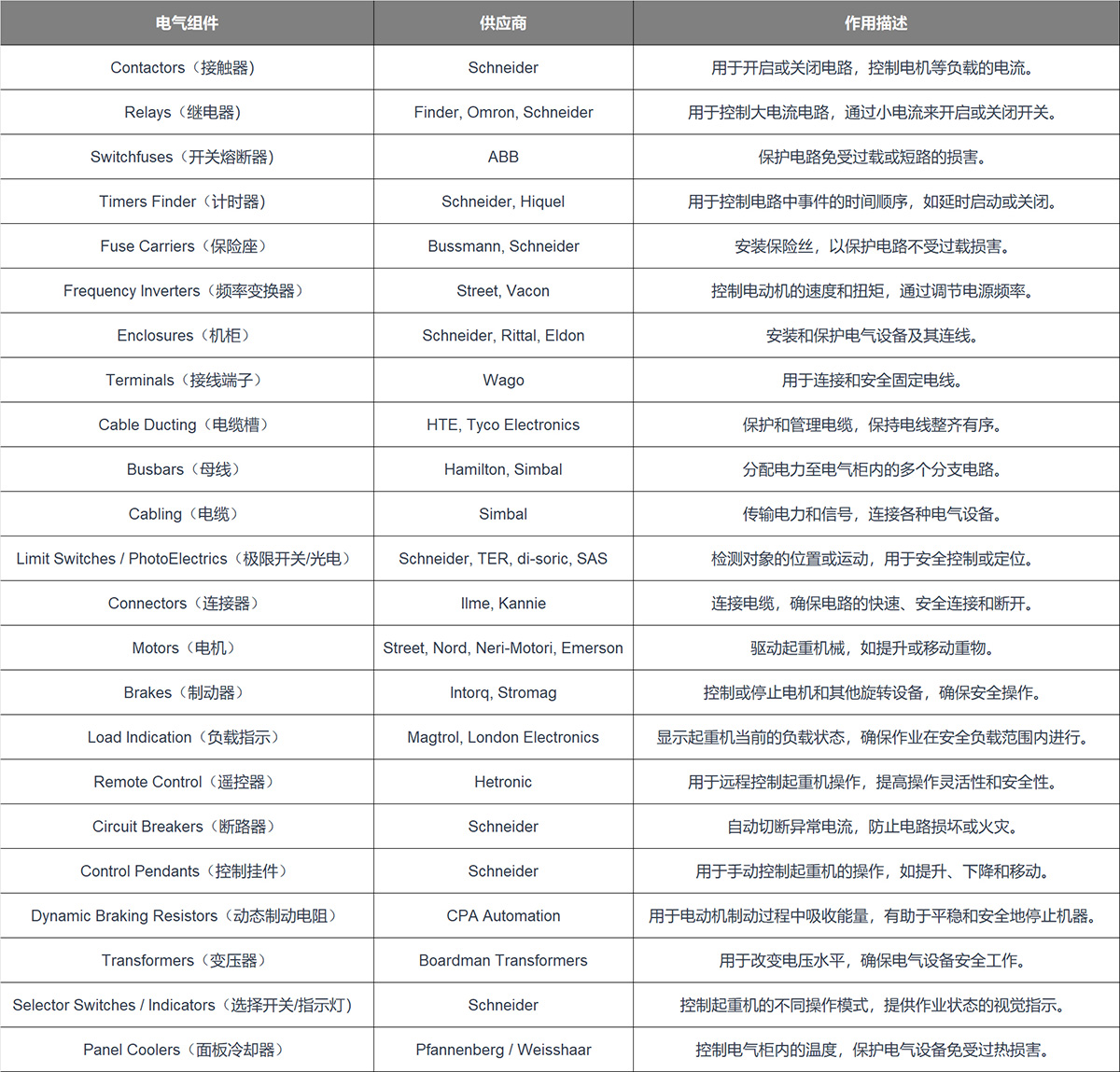

Selection of high quality electrical components

Applications

8615851586685

8615851586685

LANGUAGE

LANGUAGE