THE WORLD'S LEADING SOLUTION

Eurohoist Crane Equipment ranges from 60 kg to 600 tons or more, which is capable of meeting customers’ needs in different working conditions. Besides, Eurohoist service model brings one-stop solutions to our clients. Especially in the aspect of our technology, we are continuously making new ideas, improving product quality and perfect service system because cost saving, efficiency improvement and value creation for our customers is our long-standing target. Our lifting equipment includes Electric Chain Hoist, Steel-wire Rope Type Electric Hoist, Electrical Open Winch, Single and Double Girder Bridge Crane, Portal Crane, General-purpose Overhead Crane, Light Crane systems, Slewig Jib Crane, Explosion-proof Hoist, Explosion-proof Crane, Manual Products, etc. Otherwise, in the aspect of cargo transportation, we can also provide customers with a complete set of competitive material handling solutions

PRODUCT CENTER

Jib cranes

"A gantry-type jib crane" or "wall-traveling jib crane" is an ideal solution for workstation lifting requirements

EUROHOIST's european style jib cranes offer various configurations, including cranes installed on walls, column-mounted jib cranes, or wall-traveling jib cranes, equipped with ZX wire rope electric hoists or LX chain electric hoists.

European style jib cranes provide flexible material handling solutions with lifting capacities of up to 12.5 tons

EUROHOIST's european style jib cranes feature a unique design concept with a movable jib, allowing the hook to reach various positions in the production area. In contrast, the hook of a rotating jib crane can only move within a limited sector. The movable jib cranes are suitable for running underneath, overlapping with the main crane, and covering different areas of the building, providing great operational flexibility. It should also be noted that the building structure needs to be able to withstand the loads imposed by the crane.

Fixed base jib cranes have a simple structure, making them easy to install and maintain

They can move freely within a certain radius, allowing for adjustments to meet the lifting requirements in different locations.

The control system is highly flexible, enabling control of the arm's movement through a remote control station or controller, ensuring operator safety and production efficiency.

The jib arm is made of lightweight materials to reduce the weight of the crane body while maintaining lifting capacity, avoiding issues such as overload or unstable operation of the jib arm.

They enable quick and accurate handling of goods, saving labor and material costs, and improving work efficiency.

Goods can be suspended in the air, reducing the risks associated with manual handling and enhancing work safety.

They save space as they do not require ground support structures, maximizing space utilization.

They are adaptable to different sites, allowing for installation and adjustments based on specific site requirements, suitable for various work environments.

They cover a wide range and can handle large-sized goods.

They offer flexible operation, with adjustable hook height and angle, providing increased maneuverability.

They have low maintenance costs due to their simple structure, making it easy to repair and replace parts.

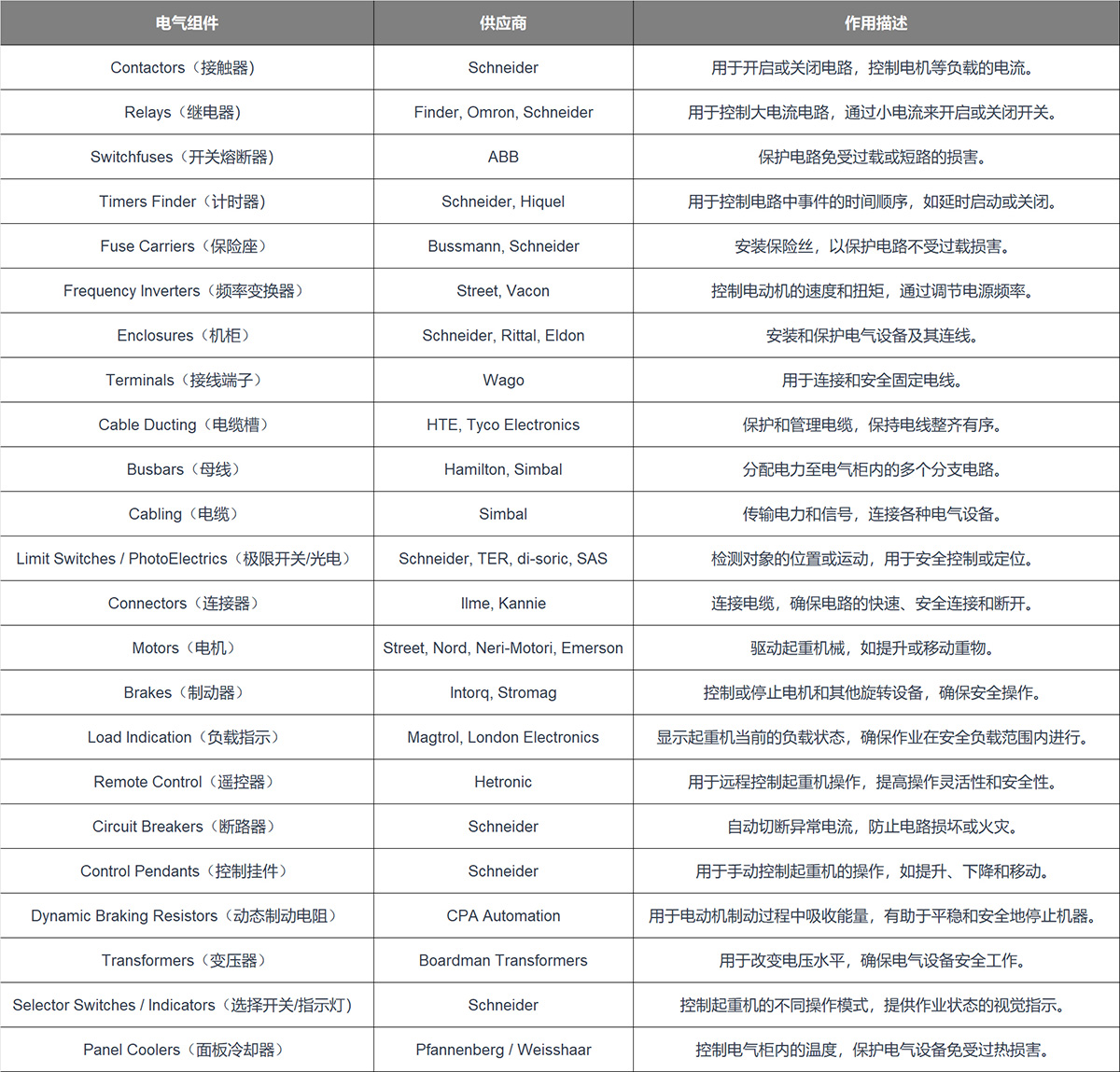

Choosing high-quality electrical components

Applications

8615851586685

8615851586685

LANGUAGE

LANGUAGE