THE WORLD'S LEADING SOLUTION

Eurohoist Crane Equipment ranges from 60 kg to 600 tons or more, which is capable of meeting customers’ needs in different working conditions. Besides, Eurohoist service model brings one-stop solutions to our clients. Especially in the aspect of our technology, we are continuously making new ideas, improving product quality and perfect service system because cost saving, efficiency improvement and value creation for our customers is our long-standing target. Our lifting equipment includes Electric Chain Hoist, Steel-wire Rope Type Electric Hoist, Electrical Open Winch, Single and Double Girder Bridge Crane, Portal Crane, General-purpose Overhead Crane, Light Crane systems, Slewig Jib Crane, Explosion-proof Hoist, Explosion-proof Crane, Manual Products, etc. Otherwise, in the aspect of cargo transportation, we can also provide customers with a complete set of competitive material handling solutions

PRODUCT CENTER

Semi-gantry cranes

Overhead crane solutions

Sometimes referred to as "gantry" or "giant cranes," operate on a two-level installed track.

Semi-gantry cranes are characterized by one side being mounted on the ground track and the other side on a steel structure-mounted track.

EUROHOIST offers solutions ranging from 1-ton single-beam to 25-ton single-beam and double-beam with a SWL of up to 600 tons.

We also produce a range of customized gantry crane designs to meet a wide range of customer needs.

Precisely calculated optimized structures

Innovative designs provide excellent solutions for low-weight semi-gantry cranes (with a maximum lifting capacity of up to 150 tons depending on the span), allowing users to save a significant amount of costs.

Dedicated crane wheels with advanced polyurethane tires enable direct operation within factory workshops, and a high-position guide roller system ensures smooth crane operation.

This solution not only saves the cost of installing guide rails but also eliminates the cost of installing equipment at different heights and the risk of serious tripping hazards in the factory workshop.

The anti-torsion box gantry and semi-gantry cranes adopt a single offset beam and a leg structure with an underslung hoist, allowing long-shaped loads to move transversely through the legs.

Rotating loads around the legs create a feeding station, forming wider storage space outside the legs, enabling the transverse movement through the legs.

Small-scale semi-gantry cranes

Simple structure: Small-scale semi-gantry cranes typically use steel frames as the main structure, equipped with electric hoists or manual hoists as the lifting mechanism. The structure is simple, compact, and easy to transport and install.

Convenient operation: Small-scale semi-gantry cranes are usually operated with remote controls or button boxes, making operation simple and convenient. Operators can operate them on the ground or at heights.

Affordable price: Compared to large-scale cranes, small-scale semi-gantry cranes are more affordable in price, with lower investment costs.

Easy maintenance: Due to the simple structure, maintenance and upkeep of small-scale semi-gantry cranes are relatively easy, with lower maintenance costs.

Wide applicability: Small-scale semi-gantry cranes are suitable for various occasions, such as workshops, warehouses, docks, etc., mainly used for lifting small goods such as steel plates, pallets, etc.

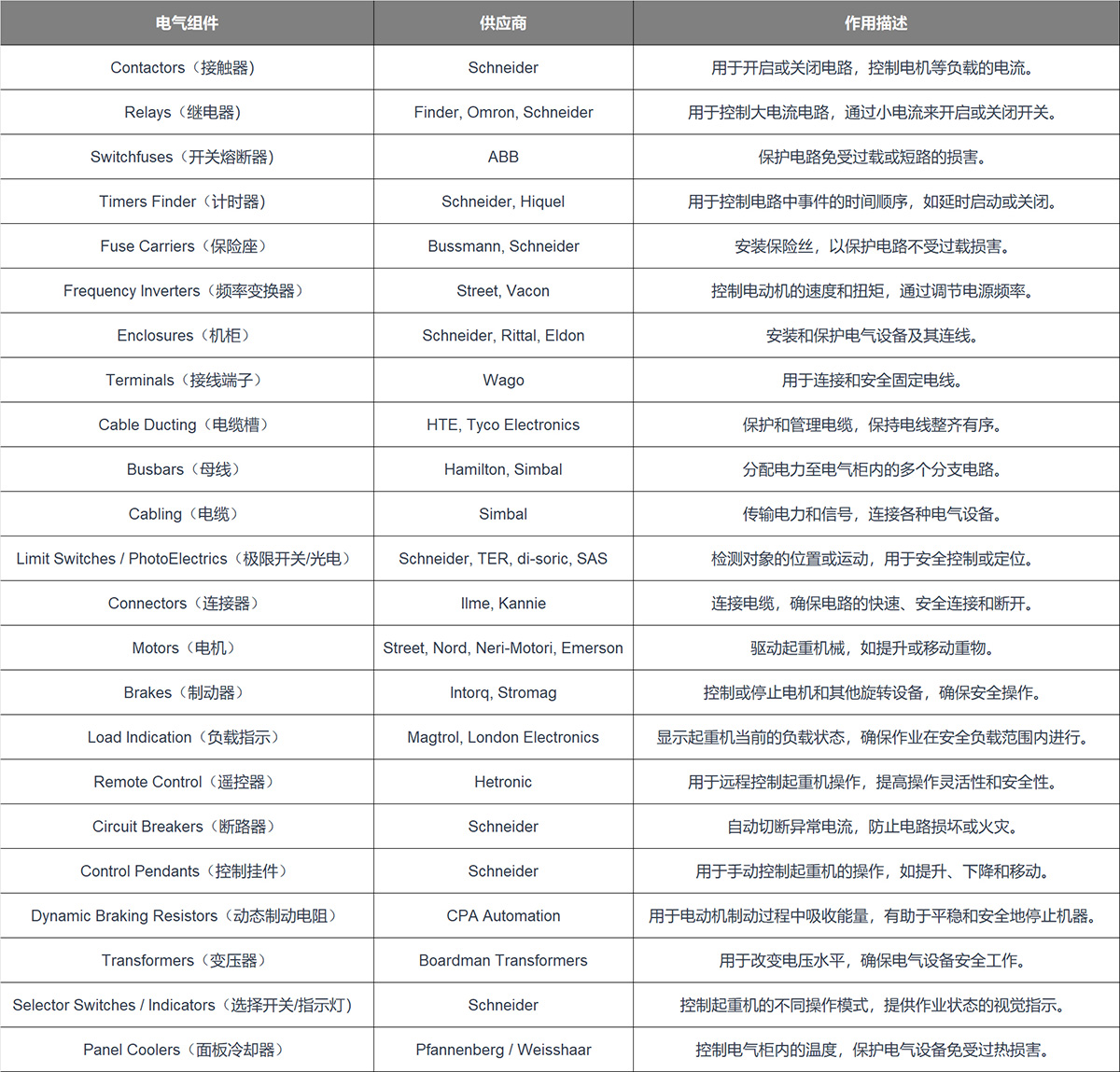

Choosing high-quality electrical components

Applications

8615851586685

8615851586685

LANGUAGE

LANGUAGE