THE WORLD'S LEADING SOLUTION

Eurohoist Crane Equipment ranges from 60 kg to 600 tons or more, which is capable of meeting customers’ needs in different working conditions. Besides, Eurohoist service model brings one-stop solutions to our clients. Especially in the aspect of our technology, we are continuously making new ideas, improving product quality and perfect service system because cost saving, efficiency improvement and value creation for our customers is our long-standing target. Our lifting equipment includes Electric Chain Hoist, Steel-wire Rope Type Electric Hoist, Electrical Open Winch, Single and Double Girder Bridge Crane, Portal Crane, General-purpose Overhead Crane, Light Crane systems, Slewig Jib Crane, Explosion-proof Hoist, Explosion-proof Crane, Manual Products, etc. Otherwise, in the aspect of cargo transportation, we can also provide customers with a complete set of competitive material handling solutions

PRODUCT CENTER

Automatic forging handling cranes

The intelligent unmanned forging handling crane has manual, semi-automatic and automatic working modes:

In semi-automatic mode the operator will operate the crane to lift the steel ring, once loaded it will select the position of the station where it wants to send the said material, once the crane is activated it will rise to a pre-programmed set height, the trolley and the big trolley will move to the selected station respectively, once positioned the operator will release the steel ring as required, and in semi-automatic mode, the manual control is used to locate the spreader, to lower it, to lift it and to release.

The fully automated mode operates only under the MES auto-run programme, which can specify all variables (X, Y, Z coordinates, extraction and storage, material data of the lifted objects, etc.).

The intelligent manufacturing of large ring forgings consists of an industrial intelligent travelling crane, its ancillary equipment and a production management system. The Intelligent Handling Crane is responsible for transporting the embryo material and steel rings within the plant.

Daily tasks include:

- Putting the blank bar into the sawmill magazine;

- Putting the single hot rings from the ring milling fork mechanism into the quenching pool inlet lifting mechanism platform; Putting the quenched wet hot single rings from the quenching pool outlet lifting platform into the palletising jigs;

- Place the palletised completed ring set onto the tempering furnace flat plate pre-set support block; place the tempered completed hot ring set onto the transfer vehicle pre-set support block;

- Place the hot ring group transferred from the transfer vehicle into the air-cooled zone pre-positioned support block;

- Place the single rings from the flaw detector into the palletising tooling.

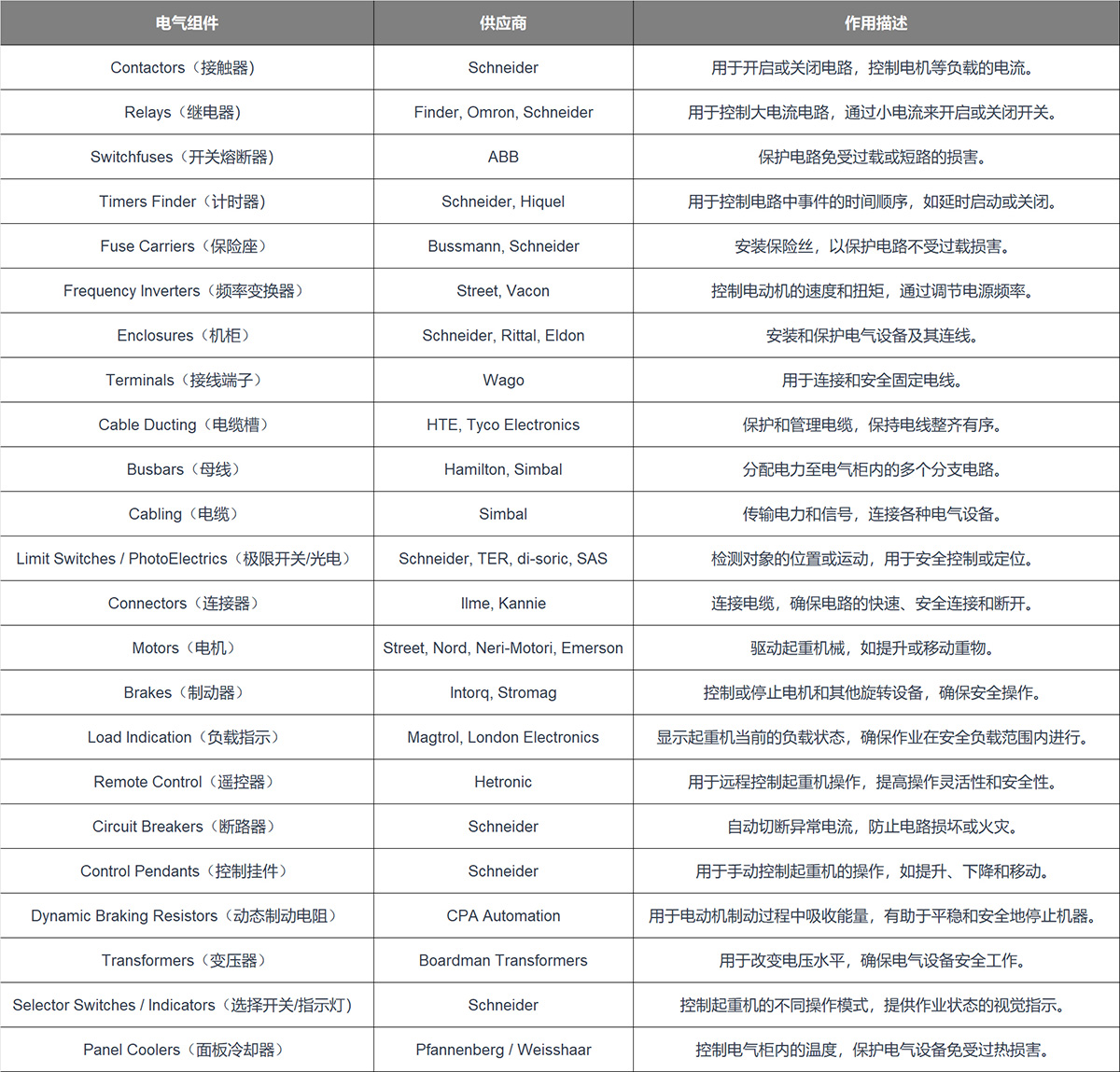

Selection of high quality electrical components

Applications

8615851586685

8615851586685

LANGUAGE

LANGUAGE