THE WORLD'S LEADING SOLUTION

Eurohoist Crane Equipment ranges from 60 kg to 600 tons or more, which is capable of meeting customers’ needs in different working conditions. Besides, Eurohoist service model brings one-stop solutions to our clients. Especially in the aspect of our technology, we are continuously making new ideas, improving product quality and perfect service system because cost saving, efficiency improvement and value creation for our customers is our long-standing target. Our lifting equipment includes Electric Chain Hoist, Steel-wire Rope Type Electric Hoist, Electrical Open Winch, Single and Double Girder Bridge Crane, Portal Crane, General-purpose Overhead Crane, Light Crane systems, Slewig Jib Crane, Explosion-proof Hoist, Explosion-proof Crane, Manual Products, etc. Otherwise, in the aspect of cargo transportation, we can also provide customers with a complete set of competitive material handling solutions

PRODUCT CENTER

Fully automatic electromagnetic cranes

All the advantages translate into economic benefits

Automation

EUROHOIST automatic control software is developed by the automation department of Ingvar Mende, which is mature and reliable, and has a high degree of freedom, and can be expanded according to different working conditions, and can be switched between fully automatic operation in normal operation and manual operation in emergency situations automatically. The optimal path for crane operation is calculated automatically by the PLC system through the software to control the automatic operation of the crane to complete a variety of operations and handling tasks (including loading/unloading/etc.), all operational tasks with high safety, high efficiency and high reliability, the three-dimensional positioning of the Intelligent Electromagnetic Crane of Inwamind, the lifting, trolley, trolley through the absolute value of the encoder and laser sensors to obtain, with high measurement accuracy, the control programme of the basic data source is more guaranteed.

Intelligent travelling crane (unmanned crane) is mainly used for the following movements of production line steel plates:

- Automatic transport from the infeed flat carriage to the cutting machine;

- Automatic transport from the infeed leveller to the temporary plate caching station;

- From the in-line plate caching station to the cutting machine;

- Palletising operations in the in-line plate caching station;

- After cutting, the whole steel plate (including parts and frames) on the cutting machine is automatically transported to the sorting platform.

Intelligent electromagnetic crane scheduling

Realise real-time monitoring of intelligent electromagnetic cranes and task scheduling of intelligent electromagnetic cranes, including warehousing, dispatching tasks, task feedback, exception handling, task stopping and deletion.

Product genealogy and traceability

Automatic tracking of material location, automatic tracking of material status, multiple information enquiry.

Operator Management

Dividing the functions and operation rights according to the different positions of operators, and automatically recording the operator's operation time, workload, and work process history.

Warehouse Management

It can carry out in-stock management, out-of-stock management, in-stock transfer management, and provide inventory management to carry out inventory manual counting intervention. Inventory query function is available.

It is possible to manage production stations, production lines, and equipment-side virtual libraries (cache libraries).

Logistics Management

Logistics task: Provide logistics task receiving, allocation, query, adjustment and other functions.

Logistics equipment scheduling: Provide logistics equipment scheduling management, including task acceptance, automated logistics equipment, manual logistics equipment, etc.

Maintenance Management

Provide crane equipment maintenance management catalogue, planning, maintenance, tracking and other functions.

Historical data management

Provide a complete set of historical data management functions.

Reliability

Provide hard disc redundancy technology to ensure data security, to cope with a large number of users accessing at the same time.

Security

Measures to ensure network security, access security, data security, and password security.

Usability

Achieve intelligent checking and intelligent prompting of input content.

Portability

Easy to install, client-side installation, update, and server-side deployment.

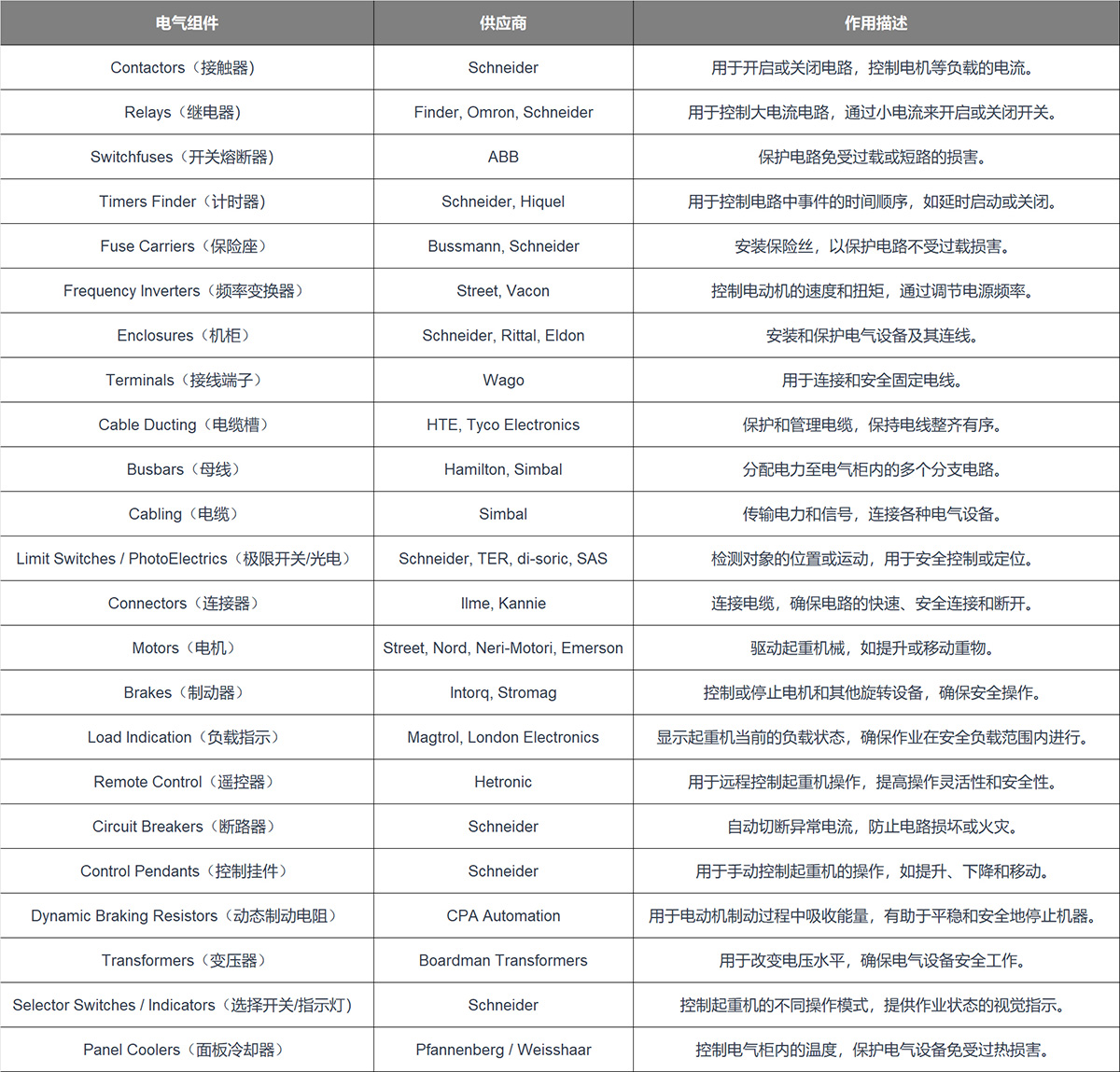

Selection of high quality electrical components

Applications

8615851586685

8615851586685

LANGUAGE

LANGUAGE